-

Traditional occupational disease control and prevention has remained prevalent in China over recent decades. There are appropriately 30, 000 new case reports of occupational diseases annually.Although China has already established a series of occupational disease prevention programs, occupational health risk assessment (OHRA) strategies continue to be a limitation.

OHRA is a tool for controlling the health risks associated with occupational hazards[1]. Through qualitative and quantitative evaluation, potential occupational hazards, doses, or conditions that result in health impacts for workers are predicted; then, the probability and degree of the harm under normal conditions can be estimated, which allows for the identification of an acceptable level of health risk and provides a scientific basis for formulating control strategies.

Recently, OHRA has become an important function of Chinese health administrative departments and their technical support organizations. However, China still does not have mature, systematic OHRA methodologies, which seriously impedes the practical implementation of OHRA in the workplace. Currently, many industrialized countries and international organizations have already promulgated OHRA guidelines to provide technical support for the assessment and control of occupational hazards.

In this article, we systematically review six types of mature international OHRA methods from the United States Environmental Protection Agency (EPA), Singapore, Australia, Romania, the International Council on Mining and Metals (ICMM), and the United Kingdom. We also analyzed the strengths and weaknesses of the models and their practical application in the field of occupational disease prevention in China. The aim of this review was to provide a basis for China and other developing countries to formulate their own OHRA guidelines or methods that meet the practical needs of occupational disease prevention and control.

-

At the end of the 19th century, Germany was the first country to establish the concept of occupational exposure limits (OELs). Recently, China has formulated occupational health standards based on the current national status, establishing OELs for 339 kinds of chemicals and 47 kinds of dust. However, there are very few hazardous substances with established OELs. Moreover, the sampling and testing processes for hazardous substances are relatively specialized, complex, and costly, which is disadvantageous for businesses (especially medium-and small-sized enterprises) to implement risk assessment. Therefore, innovative risk assessment strategies are needed as substitutes or supplements for OELs to reduce the occupational health risk among workers.

In the 1980s, the United Kingdom Health and Safety Executive (HSE) initiated the Control of Substances Hazardous to Health (COSHH) program[2]. Recently, control banding (CB) has developed into a series of qualitative and semi-quantitative risk assessment tools[3]. Starting in the 1980s, industrialized countries and international organizations successively issued OHRA guidelines or regulations. In 1983, the United States National Research Council (NRC) defined a basic process for risk assessment that included four steps: hazard identification, dose-response assessment, exposure assessment, and risk characterization.

OHRA work began in China in the 1990s when the United States EPA models were introduced in the nuclear industry field. This review primarily analyzes the principles, practical applications, and strengths and weaknesses of six models applied in China, i.e. the United States EPA model; models from Singapore, Australia, and Romania; the International Council on Mining and Metals (ICMM) model; and the United Kingdom Control of Substances Hazardous to Health Essentials (COSHH Essentials) model.

-

The principles, types, scopes, procedures, risk classifications, strengths, and weaknesses of the six models were analyzed qualitatively based on a literature review.

(1) Principles of the EPA model: The United States EPA established a series of risk assessment guidelines including carcinogens, mutagens, reproductive toxins, and hazards to human health. Among these, the supplemental inhalation risk assessment guidelines[4] in parts A and F of the Human Health Risk Assessment Manual provided technical guidance for the risk assessment of airborne toxic chemicals in the workplace.

The EPA inhalation risk assessment includes two components: carcinogenic and non-carcinogenic risk assessments. Both components use calculations for estimating exposure concentrations (EC) and risk assessment.

1) Estimating exposure concentrations (ECs):

$${\rm{EC = }}\left( {{\rm{CA \times ET \times EF \times ED}}} \right){\rm{ \div AT}}$$ (1) In equation (1), EC (µg/m3) is the exposure concentration; CA (µg/m3) is the contaminant concentration in the air; ET (h/d) is the exposure time; EF (d/y) is the exposure frequency; ED (y) is the exposure duration; and AT is the averaging time (lifetime in year × 365 days/year × 24 h/day).

2) Risk assessment:

Equation 2 is used for cancer risk assessment:

$${\rm{Risk = IUR \times EC}}$$ (2) In equation (2), IUR (µg/m3)-1 is the inhalation unit risk, indicating continuous exposure to 1 µg/m3 of a chemical in the air that is estimated to exceed the upper limit of lifetime cancer risk. Generally, a value of 10-4 serves as the limit for carcinogenic risk among occupational populations. Non-carcinogenic risk is evaluated through the calculation of the hazard quotient (HQ): HQ = EC / RfC. In this equation, RfC represents the reference concentration for inhalation toxicity. The limit for HQ is considered to be 1.

The detailed IUR and RfC values are available on the United States EPA website.

(2) Practical application of the EPA model: The EPA model can be applied to Chinese industries with a high incidence of acute and chronic occupational poisoning[5], such as that from chemicals, metallurgy, and construction. Zhang et al.[6] applied this model to assess the occupational health risk at a paint machinery manufacturer and found the core parameters of the technical principles of the EPA model were appropriate for occupational hazard assessment in the workplace. Leng et al.[7] deemed that the model focuses on specific health outcomes and can objectively reflect the level of risk to human health induced by chemical inhalation exposure. Zhou et al.[8] investigated the appropriateness and feasibility of applying the EPA model to papermaking, chemical, and electroplating industries and found high levels of risk for critical jobs in all three industries. The EPA model was able to identify occupational hazards and critical control points more easily.

(3) Principles of the Singaporean model: The Ministry of Manpower of Singapore established a 'Semi-quantitative Method to Assess Occupational Exposure to Harmful Chemicals'[9] and formulated a guideline for assessing chemical exposure. In this model, risk levels are calculated based on hazard ratings (HR) and exposure ratings (ER), as shown in Equation 3:

$${\rm{Risk = }}\sqrt {{\rm{HE}} \times {\rm{ER}}} $$ (3) The HR is assigned based on the carcinogenicity classifications established by the American Conference of Governmental Industrial Hygienists (ACGIH) and the International Agency for Research on Cancer (IARC). The ER is based on the ratio of the exposure level and OEL. If the exposure concentration is not available, exposure indices (EIs) can be used to determine the ER, as shown in Equation 4:

$${\rm{ER = }}{\left[ {E{I_1} \times E{I_2} \times , \ldots ,E{I_n}} \right]^{\frac{1}{n}}}$$ (4) In equation (4), n is the number of exposure factors, which include vapor pressure, ratio of odor threshold to permissible exposure level, particle size, hazard control measures, amount of chemicals used per week, and duration of work per week. EIs denote the exposure factor indices.

(4) Practical application of the Singaporean model: Using the Singaporean model as a foundation, Huang et al.[10] improved the determination of hazard ratings and exposure ratings to select priority risk control strategies. Jiang et al.[11] found that this model was suitable for occupational health professionals from grass-roots organizations to perform OHRA because of the availability of data for risk assessment. Moreover, Wang et al.[12] found that the concentrations of toxic chemicals such as lead dust, lead smoke, and sulfuric acid at a lead-acid battery corporation were all within occupational exposure limits, but their associated health risk reached moderate to high levels.

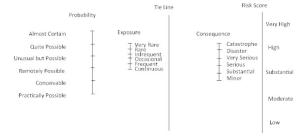

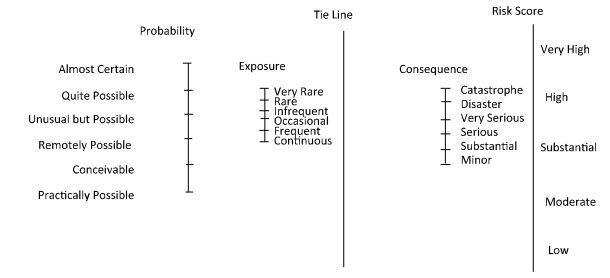

(5) Principles of the Australian model: The University of Queensland in Australia formulated the 'Occupational Health and Safety Risk Assessment and Management Guideline, ' which can assess risk level, using a manual diagram method or a calculator, by analyzing the identified exposure levels, possible consequences, and likelihood of each hazard (Figure 1)[13].

Figure 1. Australian manual diagram of the risk score calculator[13].

(6) Practical application of the Australian model: By conducting OHRA using the Australian model in a battery production corporation, Wang et al.[14] found that workers exposed to sulfuric acid had a 'high' risk for occupational health effects, and other hazards (e.g., lead fume and dust) were associated with a 'very high' risk. This model is helpful for determining critical control points for occupational hazards in factories, but it may be undervalued or overvalued because of the subjective assessment of probability, exposure, and possible consequences.

(7) Principles of the Romanian model: Based on European standards (CEI 812/85), the Ministry of Labor and Social Protection of Romania promulgated a mandatory standard known as the Risk Assessment Method for Occupational Accidents and Diseases[15]. The severity level of the maximum consequence on the human body and the level of probability for that consequence occurring are assessed for each risk factor. Then, a matrix method is applied to estimate the risk level. The total risk level in the workplace is calculated using the following equation:

$${N_r} = \frac{{\sum\nolimits_{i = 1}^n {{r_i} \cdot {R_i}} }}{{\sum\nolimits_{i = 1}^n {{r_i}} }}$$ (5) In this equation, Nr is the total risk level in the workplace and ri is the rank of risk factor i, which is the same as the risk rank. Ri is the level of risk for risk factor i and n is the number of risk factors.

(8) Practical application of the Romanian model: To conduct a risk assessment of key work sites within the papermaking, chemical, and electroplating industries, Zhou et al.[16] used three types of risk assessment models that incorporated the Romanian model and found the risk assessment results of the three models were generally consistent. Li[17]found that the risk assessment results using the Romanian method were generally consistent with those from on-site detection and occupational health physical examinations at a coal-fired power plant.

(9) Principles of the International Council on Mining and Metals (ICMM) model: The ICMM proposed Good Practice Guidance on OHRA for the mining industry[18]. Risk level (RR) is calculated using the following quantitative rating method:

$${\rm{RR = C \times PrE \times PeE \times U}}$$ (6) In this equation, C is the consequence, PrE is the probability of exposure, PeE is the period of exposure, and U is the uncertainty. Risk is classified at one of five levels, ranking from tolerable to intolerable risk levels.

In addition, a matrix method in this model can be applied, including matrix combinations of health hazards and the probability of an exposure occurring to a similar exposure group or during a process. This matrix method incorporates a four-level risk ranking, from no/very low to critical risk.

(10) Practical application of the ICMM model: Li et al.[19] used both the quantitative rating method and the matrix method to conduct risk assessment at fired power plants. As verified by on-site detection, occupational health physical examination, or reports from the literature, the results of the model appeared to be relatively reliable. Zhou et al.[20] found that the quantitative rating method was more likely to result in a higher risk result than did the matrix method at a financial machinery engineering project.

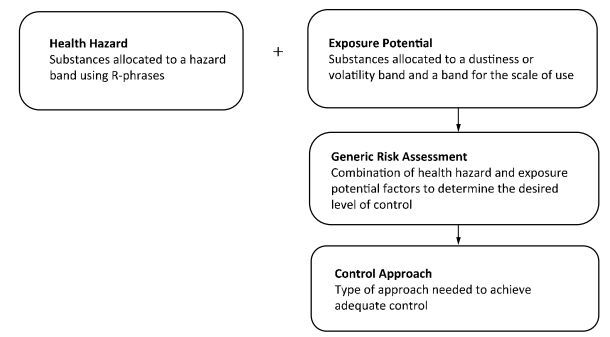

(11) Principles of the COSHH Essentials model: Using the control band as a basis, the United Kingdom Health and Safety Executive formulated the Control of Substances Hazardous to Health Essentials (COSHH Essentials) model[2-3]. This model simultaneously considers both the health hazard and exposure levels of chemical substances (solid or liquid) and uses risk assessment to recommend the control level (Figure 2). The control strategies with four levels are listed in Table 1.

Figure 2. Flowchart of the COSHH essentials risk assessment process[2].

Levels Strategies Control Approach 1 General ventilation: Good standard of general ventilation and good working practices. Control Approach 2 Engineering control: Ranging from local exhaust ventilation to ventilated partial enclosure. Control Approach 3 Containment Control Approach 4 Special: Seek expert advice. Table 1. Occupational Hazard Control Strategy Levels[2]

(12) Practical application of the COSHH Essentials model: Chen et al.[21] applied the COSHH Essentials to construct an occupational health pre-assessment for a construction project using several processes as examples (namely, a plastic processing step and dust-producing step during lithium battery production). The authors considered this model to be operationally convenient. To account for the insufficient classification of control methods, this method can be used in combination with air monitoring procedures. Lin et al.[22] used the COSHH Essentials to identify occupational hazards in the production process of a hydrogen storage alloy powder production line and provided measures for classification control of existing chemicals. Results suggest the model could be applied broadly in chemical industries.

-

A qualitative comparison of the OHRA methodologies is listed in Table 2, based on the literature review. The assessment results of the EPA model are more scientifically robust and highly toxicological data, owing to the semi-quantitative reliable since the model can quantitatively assess the risks for chemicals. However, this model is limited only to some chemical poisons. The Singaporean model does not require much epidemiological and risk assessment method with operability and applicability. The Australian model uses a manual diagram and provides a broad scope of evaluated substances. However, biases are difficult to avoid when determining hazard and exposure levels in this model. Both the Romanian model and ICMM model provide a broad scope of evaluated substances. However, they rely on subjective judgment when determining hazard and exposure levels. The COSHH Essentials model is easy to understand. Nevertheless, it is difficult to fully consider the effects of accelerating diffusion caused by heating, stirring, spraying, ventilation, sonication, and other actions when judging liquid volatility[23]. Sometimes, there also is an overestimation of risk when using the ICMM and COSHH Essentials models. For example, a study was conducted based on parallel testing of the International Chemical Control Toolkit (ICCT) toolbox, which is based on the COSHH Essentials and the Singaporean model. Since the results of the two methods of assessment differ by 1-2 levels, overestimates of risk occur more easily with the ICCT than with the Singaporean model; therefore, even stricter control measures are indicated by the ICCT[24].

Model Year Type Scope Risk Classification Strengths Weakness EPA[4] 1980s Quantitative Chemicals 2 levels 1. Quantitative assessment for carcinogenic and non-carcinogenic risks 2. Scientific values of RfC and IUR based on epidemiological or toxicological data 1. Limited to chemical poisons with IUR and RfC values 2. No consideration for personal protective equipment 3. Difficult to differentiate multiple risk levels Australian[13] 2011 Qualitative Chemicals, physical factors, and dust 5 levels 1. Good operability and ease of use 2. Broad scope 3. Appropriate for middle-and small-sized businesses 1. Relies on subjective judgment 2. Requires professional knowledge Romanian[15] 1998 Qualitative Chemicals, physical factors, and dust 7 levels 1. Broad scope 2. Calculation of total risk level 1. Relies on subjective judgment 2. Difficult to judge the probability of a consequence occurring Singaporean[9] 2005 Semi-quantitative Chemicals and dust 5 levels 1. Makes up for shortcomings of quantitative and qualitative methods 2. Usage of exposure index method when air monitoring data are missing 3. Appropriate for occupational health technicians in grass-roots units 4. Corresponding control strategy Relatively crude classification in terms of exposure index ICMM[18] 2009 Qualitative Chemicals, physical factors, and dust 4 or 5 levels 1. Broad scope 2. Application to various industries 1. Relies on subjective judgment 2. Overestimation of risk using the quantitative rating method COSHH Essentials[2-3] 1980s Qualitative Chemicals and dust 4 levels 1. Simple and convenient operation 2. Focus on middle-and small-sized businesses 3. Provides control measures 1. Overestimation of risk levels 2. Occurrence of bias when judging liquid volatility Table 2. Qualitative Comparisons between Six OHRA Models

Based on the present analysis, we reached the following conclusions: (1) OHRA, which is part of an integrated group of occupational disease prevention measures, can be used to assess and control occupational hazards; (2) qualitative OHRA can also serve as a substitute for OEL assessment or as a screening approach, and (3) the scope, and principles of each type of OHRA are not exactly the same, each having its own strengths and limitations. Therefore, quantitative, semi-quantitative, and qualitative methods can be applied in combination when conducting OHRA.

Further research should be conducted in China to address at least three aspects. First, the application of OHRA methodologies in key industries should be performed to evaluate their appropriateness. Second, comparative quantitative studies of different OHRA methods should be conducted. Third, research regarding the optimization or modeling of OHRA methods should be a priority.

Research Progress in Occupational Health Risk Assessment Methods in China

doi: 10.3967/bes2017.082

the Joint Projects of the National Health and Family Planning Commission of China and the Health Bureau of Zhejiang Province WSK 2014-2-004

the Natural Science Foundation of China 81472961

- Received Date: 2017-02-08

- Accepted Date: 2017-06-28

| Citation: | ZHOU Li Fang, TIAN Fang, ZOU Hua, YUAN Wei Ming, HAO Mo, ZHANG Mei Bian. Research Progress in Occupational Health Risk Assessment Methods in China[J]. Biomedical and Environmental Sciences, 2017, 30(8): 616-622. doi: 10.3967/bes2017.082 |

Quick Links

Quick Links

DownLoad:

DownLoad: