-

Metal alloys, especially stainless-steel, are widely used in the preparation, production and storage of food, because of their corrosion resistance and barrier properties. Most food contact (FC) stainless-steel articles are designed for repeated, long-term use, and the migration of heavy metals is regarded as the main safety risk when they make contact with food. Manganese (Mn) is an important alloying element in stainless-steel, and its potential to migrate has caused considerable consumer concern.

Mn is also an essential micro-element which plays an important role in human metabolism. However, excessive Mn exposure, primarily occupational exposure, has adverse effects on the human nervous system, such as manganism, or Mn poisoning [1]. According to the Scientific Committee for Food, insufficient data on animals or humans is available to derive a Tolerable Upper Intake Level (UL) for Mn [2]. Nevertheless, a no-observed-adverse-effect-level (NOAEL) and UL of 11 mg/day for adults were set by the U.S. Institute of Medicine of the National Academy of Sciences, as no adverse effects have been reported at exposure levels up to 10.9 mg/day [3]. A UL of 11 mg/day for adults was also recommended by the Chinese Nutrition Society [4].

In terms of risk management, the European Directorate for the Quality of Medicines & Healthcare (EDQM) has recommended a Specific Release Limit (SRL) of 1.8 mg/kg for Mn in all FC metal products, using citric acid (5 g/L) and artificial tap water as food simulants [5]. A Specific Migration Level (SML) for Mn of 0.1 mg/kg was set by the Italian Ministry of Health, using acetic acid (3% w/v) and water as food simulants [6].

However, the risk arising from Mn in stainless-steel FC products has not been systematically assessed in China. The risk of Mn ingestion by Chinese residents from stainless-steel products is unknown, because of a lack of risk assessment data. Therefore, the limit on Mn migration from FC stainless-steel products has not yet been specified in the China National Food Safety Standards for FC Metal and Alloy Products (GB 4806.9-2016) [7]. Studying the migration of Mn from stainless-steel products on the Chinese market and carrying out a safety assessment are of great significance for understanding the intake of Mn by the Chinese population from stainless-steel products and the safety management of FC metal products.

In this study, 124 sets of new stainless steel FC products were collected from supermarkets, shopping malls and online shopping stores, including cutlery, kettles, pots, flatware and other daily-use kitchenware. The samples were selected randomly and were typical of the stainless-steel kitchen utensils used by Chinese residents on an everyday basis. Each set of samples was divided into two groups (A and B), each made up of two parallel test samples and one retention sample and was tested using different test procedures, i.e., using different Mn migration test conditions and food simulants. Group A migration tests followed the requirements for stainless steel products specified in GB 4806.9-2016 [7]: acetic acid (4% v/v) as the food simulant and the test condition of boiling the item acetic acid for 0.5 hours, followed by 24 h at room temperature. Group B followed migration test requirements for other metals specified in GB 4806.9-2016 [7]. If a sample is unlikely to contact acidic food during normal use (such as electric kettles), artificial tap water was used as the food simulant, whereas citric acid (5 g/L) was used for samples likely to contact acidic food. Migration test conditions were selected depending on actual use conditions, such as two hours at boiling temperature for cookware and two hours at 70 °C for tableware. All pretreatment processes followed the procedures specified in GB 5009.156-2016 [8].

Since all the samples were reusable products, they were subjected to migration tests thrice, each time using fresh food simulant. After the pretreatment was completed, the soaking solution was stored in polyethylene bottles and Inductively coupled plasma-atomic emission spectroscopy (ICP-AES; ICP 6500, Thermo Fisher Scientific, Waltham, MA) was used to determine the Mn content in the parallel samples. The optimized operating parameters used were: wavelength 257.6 nm, radio-frequency power 1,150 W, atomizer flow 0.60 L/min, auxiliary gas flow 0.5 L/min, plasma gas flow 12.0 L/min, peristaltic pump flow 1.50 mL/min, light source stability delay 15 s, axial observation mode). If the Mn content of two parallel samples differed greatly (Relative Deviation > 10%), the retention sample was also analyzed and the outlying value excluded.

Mn content in the soaking solution of each sample was converted according to the surface area-volume ratio (S/V) of the sample to obtain the migration result. The average value of two samples was taken as the migration result of each sample set. All samples were classified into one of eight categories according to their characteristics and conditions of use, and the mean value and 95 th percentile (P95) for each category and the entire sample set were calculated, respectively. Samples with undetectable Mn concentrations were assigned as 1/2 of the detection limit (LOD = 0.001 mg/kg).

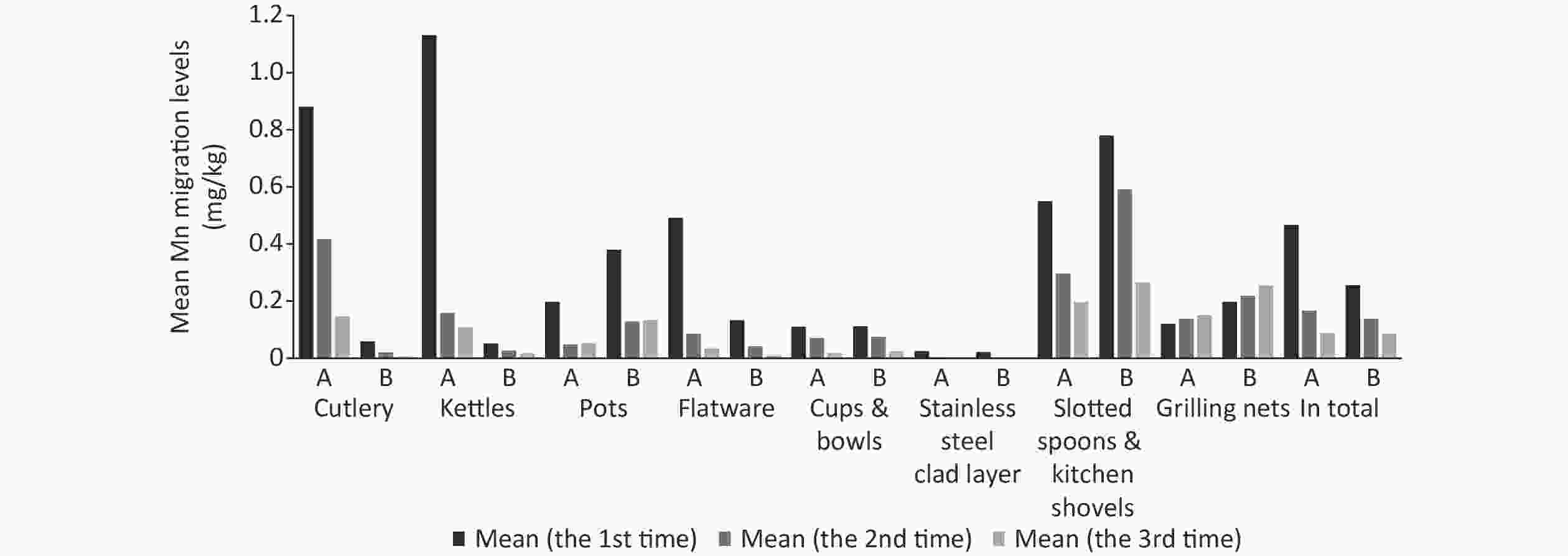

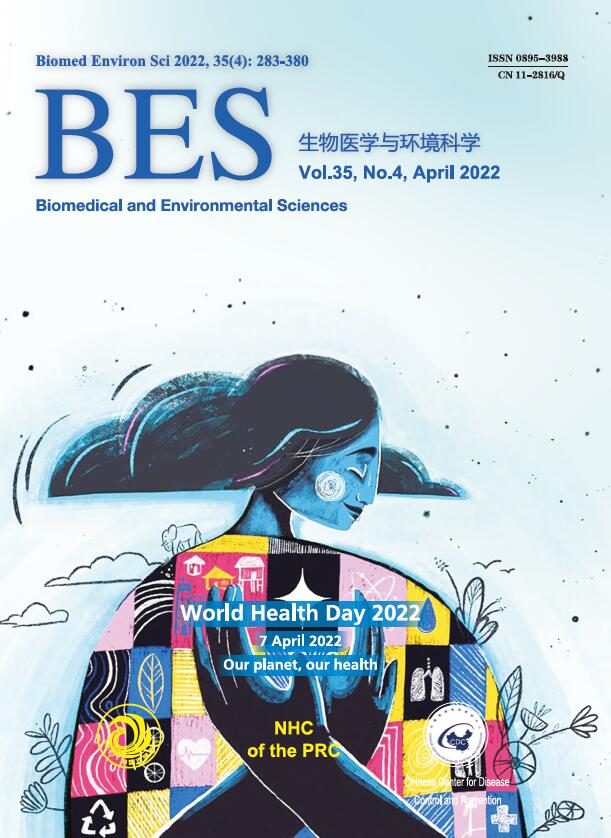

The Mn migration test results of 124 sample sets are summarized in Table 1, by product category and migration test mode.

Categories Sample sets Group2 Number of test Mean Max Min P95 Cutlery (cleavers, chef knives & santoku knives) 23 A The 1st time 0.880 6.436 0.004 1.679 The 2nd time 0.417 3.454 < LOD 0.810 The 3rd time 0.147 0.702 < LOD 0.256 B The 1st time 0.059 0.384 0.004 0.098 The 2nd time 0.021 0.152 < LOD 0.040 The 3rd time 0.006 0.035 < LOD 0.010 Kettles (electric kettles, wine kettles, oil kettles etc.) 9 A The 1st time 1.131 4.878 0.009 2.236 The 2nd time 0.159 0.659 0.003 0.303 The 3rd time 0.111 0.507 0.002 0.221 B The 1st time 0.053 0.212 < LOD 0.100 The 2nd time 0.028 0.109 < LOD 0.053 The 3rd time 0.018 0.068 < LOD 0.034 Pots (stir fry pans, sauté pans, stock pots etc. ) 33 A The 1st time 0.198 1.493 < LOD 0.524 The 2nd time 0.049 0.330 < LOD 0.138 The 3rd time 0.053 0.414 < LOD 0.1469 B The 1st time 0.380 2.649 < LOD 1.049 The 2nd time 0.129 0.878 < LOD 0.350 The 3rd time 0.134 0.958 < LOD 0.373 Flatware (forks, spoons & chopsticks) 21 A The 1st time 0.492 3.621 0.007 0.907 The 2nd time 0.087 0.343 < LOD 0.136 The 3rd time 0.035 0.218 < LOD 0.056 B The 1st time 0.133 0.842 0.008 0.231 The 2nd time 0.043 0.524 < LOD 0.092 The 3rd time 0.009 0.043 < LOD 0.014 Cups & bowls 14 A The 1st time 0.111 0.374 0.008 0.182 The 2nd time 0.071 0.321 < LOD 0.128 The 3rd time 0.019 0.078 0.004 0.032 B The 1st time 0.113 0.410 0.002 0.180 The 2nd time 0.075 0.365 < LOD 0.134 The 3rd time 0.024 0.010 < LOD 0.039 Stainless steel clad layer (on bowls & flatware) 3 A The 1st time 0.025 0.046 0.013 0.046 The 2nd time 0.004 0.006 0.002 0.007 The 3rd time 0.001 0.002 < LOD 0.002 B The 1st time 0.021 0.044 0.010 0.044 The 2nd time 0.003 0.006 < LOD 0.006 The 3rd time 0.001 0.003 < LOD 0.003 Slotted spoons & frying spatula 15 A The 1st time 0.550 2.476 0.010 0.977 The 2nd time 0.297 1.470 < LOD 0.517 The 3rd time 0.198 0.822 < LOD 0.334 B The 1st time 0.780 3.360 0.031 1.367 The 2nd time 0.591 3.278 < LOD 1.067 The 3rd time 0.266 1.125 0.005 0.468 Grilling grids 6 A The 1st time 0.121 0.315 0.006 0.219 The 2nd time 0.139 0.347 < LOD 0.252 The 3rd time 0.152 0.368 < LOD 0.273 B The 1st time 0.198 0.484 0.002 0.377 The 2nd time 0.219 0.587 < LOD 0.412 The 3rd time 0.255 0.824 < LOD 0.538 In total 124 A The 1st time 0.467 6.436 < LOD 0.645 The 2nd time 0.167 3.454 < LOD 0.239 The 3rd time 0.089 0.822 < LOD 0.117 B The 1st time 0.256 3.360 < LOD 0.358 The 2nd time 0.138 3.278 < LOD 0.206 The 3rd time 0.087 1.125 < LOD 0.125 Note. 1Limit of Detection (LOD): 0.001 mg/kg of simulant. 2Group A: choosing acetic acid (4% v/v) as the food simulant, and boiling the item acetic acid for 0.5 h, followed by 24 h at room temperature as the test condition. Group B: choosing artificial tap water (for samples unlikely to contact acidic food) or citric acid

(5 g/L) (for samples likely to contact acidic food) as the food simulant, and migration test conditions were selected depending on actual use conditions.Table 1. Migration of Mn (mg/kg of simulant)1 from food-contact stainless steel products, using different food simulant solutions and migration test conditions (Groups A and B)

The Mn migration test results under group A test conditions were generally higher than those for group B (Table 1). For group A, the maximum values from the first and second migration tests were both from cutlery products (Table 1, first category). The maximum value from the third migration test was from the slotted spoons and frying spatula category. For group B, the maximum values of the first, second and third migration tests were all from the slotted spoons and frying spatula category.

For most of the samples, in both groups A and B, the Mn migration decreased significantly in the three migration tests; 87 out of 124 sample sets (70.2%) in group A and 98 out of 124 (79.0%) in group B showed a downward migration trend. However, some samples which demonstrated anomalous migration trend. In group A, four sample sets (3.2%), showed a trend of successive increase; while in group B, two sets (1.6%) increased. Irregular trends were seen in the remaining sets: 33 in group A (26.6%) and 24 in group B (19.4%). Part of the irregular fluctuation amplitude was very small which may be caused by the detection errors.

Average Mn migration in most sample categories exhibited a downward trend, with the exception of grilling grids (Figure 1). This would be expected when testing new items, as successive tests would deplete Mn levels at the surface of the item. However, the spot welds on the grilling grids were non-stainless steel, which appears to have corroded in the acidic food simulant solutions, resulting in a gradual increase in Mn migration.

Figure 1. Mean Mn migration levels for triplicate migration tests under different test conditions (A and B) for different categories of stainless-steel products. Cutlery includes cleavers, chef knives and santoku knives; kettles include electric kettles, wine kettles and oil kettles; pots include stir fry pans, sauté pans and stock pots; flatware refers to forks, spoons and chopsticks; stainless-steel clad layer includes bowls and flatware; in total means the average of all 124 samples.

The results of the three migration tests were subjected to Z-Testing, to check for differences between the Mn migration results of groups A and B. The migration results from the first migration test were significantly different (z1 = 2.01, > 1.96) between groups A and B, and the average migrated amount from group A was higher. However, there was no significant difference between the migration results of groups A and B in either the second (z2 = 0.58, < 1.96), or the third migration test (z3 = 0.08, < 1.96). The mean and P95 values of the three migration tests in groups A and B show that the differences between the first, second and third migration test results decreased successively. After three migration tests, a relatively low Mn migration levels emerged in stainless-steel, which is not attributable to differences in food simulants, or test conditions.

Although there was no significant difference in the third time migration levels between groups A and B for the overall samples, the migration test results of groups A and B were different between the sample categories and correlated with their actual conditions of normal use.

The level of Mn migration in group B tests was higher for products that are often used for cooking and expected to come into contact with acidic foods, such as pots, slotted spoons, frying spatula and grilling grids. This indicates that using citric acid (5 g/L) as the food simulant and selecting migration test conditions that reflect actual use conditions was an appropriate choice for these products. Group A had higher migration levels from cutlery, flatware and kettles. This may be because the test conditions stipulated in GB 4806.9-2016 were too harsh for cutlery and flatware items that are often used at room temperature and only occasionally come into contact with hot foods for a short time (< 30 minutes). Kettles, which are mostly filled with water or liquor, but are exposed to high heat, were tested with artificial tap water as the food simulant for group B. The migration level of group B was well below that of group A, because of the much weaker corrosive effect of artificial tap water, compared with acetic acid (4% v/v). Moreover, there was no significant difference between groups A and B, in the levels of migration in cups, bowls and stainless-steel clad layers (on bowls and flatware). Most cups and bowls are expected to come into contact with hot foods for a relatively long period (hours to days) under extreme use scenarios.

The mean Mn migration levels from grilling grids, slotted spoons and frying spatula were relatively high compared to the average of all the samples in both groups A and B, whereas flatware, cups and bowls, and stainless-steel clad layers (on bowls and flatware) had lower levels of migration. The variance in Mn migration between different categories is related to their conditions of normal use, i.e., products used under more severe conditions (higher temperature, or longer exposure to food) produced higher levels of migration. When citric acid or artificial tap water was used as the food simulant and test conditions were chosen according to the actual use conditions, migration was higher under the more severe conditions, indicating that the group B conditions were a better indication of actual Mn migration during everyday use of the FC utensils.

As discussed above, the Mn migration results of group B appeared to be a better reflection of migration during normal use, so the third migration test results of group B were used to assess the safety of Mn in stainless steel products. Since the products tested were all new, the first test would be expected to give an atypically high Mn migration result, so the third test should best reflect the levels of migration during long-term repeated use of the products [5].

Due to the lacking of necessary dietary intake data for the Chinese population and the observed migration of Mn was relatively low, so screening method was selected for the dietary exposure of Mn [9]. The dietary exposure was calculated as follows:

$$\begin{split} &{\rm{Mn \;Daily\; Dietary\; Exposure}} \;=\; \\ &{\rm{Mn \;Migration\; Level}}\;\times\; {\rm{Dietary\; Food\; Intake}} \end{split}$$ (1) The Chinese Dietary Guidelines recommend a daily intake of 2.6–3.5 kg of food (including water) for the Chinese population [10]. Using the conservative assumption that an adult will consume 3 kg of food that contacts stainless-steel products every day, the average and P95 intake of Mn for adults were less than 15% of the UL value, even for people with high exposure to grilling grids, slotted spoons and frying spatula, which had relatively high migration levels.

Under extremely high exposure conditions, it was assumed that the exposed population consumed 3 kg of food repeatedly exposed to multiple stainless-steel products daily. Considering the dietary patterns and cooking habits of the Chinese population, processing food with stainless-steel cutlery, pots, slotted spoons, frying spatula, flatware, cups and bowls was considered to be the most extreme exposure scenario. Under these conditions, the mean, P95 and maximum calculated exposures were 1.3, 2.7, and 6.8 mg/person per day, equivalent to 12%, 25%, and 62% of the UL value, respectively. According to the Chinese Nutrition Society [4], the average dietary intake of Mn is 5.9 mg/d in the urban population and 6.4 mg/d in the rural population. Adding the P95 exposure of Mn from stainless steel to the dietary intake, the total intake of Mn is still within the safety limit (11 mg/d), whereas the maximum exposure scenario, which is highly unlikely to occur, would result in excessive Mn intake.

These dietary exposure results suggest that the safety risk resulting from migration of Mn from stainless steel products is very low for the Chinese adult population, so Mn migration does not appear to be a priority safety issue for food contact stainless steel products. However, this study excluded safety assessments for special population groups, such as infants, or pregnant women, for lack of necessary data. Further research is needed to extend safety assessments to the whole population.

Acknowledgments We would like to thank Dr. Haixia Sui for the direction of safety assessment.

Conflicts of Interest The authors declare no conflict of interest.

Study of Migration and Safety Assessment of Manganese (Mn) from Food Contact Stainless-Steel Products in China

doi: 10.3967/bes2022.048

- Received Date: 2021-11-11

- Accepted Date: 2021-12-28

| Citation: | ZHANG Hong, XING Hang, LIU Zai Mei, LI Qian Yun, CHEN Shao Hong, ZHU Lei. Study of Migration and Safety Assessment of Manganese (Mn) from Food Contact Stainless-Steel Products in China[J]. Biomedical and Environmental Sciences, 2022, 35(4): 361-365. doi: 10.3967/bes2022.048 |

Quick Links

Quick Links

DownLoad:

DownLoad: