-

Personal protective equipment (PPE) plays a key role in protecting healthcare workers (HCWs) from highly infectious diseases. Appropriate use of PPE based on the level of exposure can prevent severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) infection of otolaryngologists[1]. However, the high demand of single-use-plastic PPE was frequently stretched beyond capacity in outbreak of pandemic situations. The shortage of protective materials drove strategies for deployment of effective methods of PPE reuse such as vaporized hydrogen peroxide, ultraviolet light and moist heat[2].

As an important part of PPE, medical protective clothing has excellent liquid-barrier properties. It can, thus, prevent the risks from exposure to hazardous substances, including potentially infectious body fluids, and can minimize the risk of cross-infections[3]. At present, the phenomenon of spraying disinfectants on medical protective clothing has been found in the work of preventing and curing infectious diseases. A experimental study found that alcohol was shown to be effective in reducing microbial loads from different places of firefighter’s suits[4]. Meanwhile, following guidance for apron or gown removal led to less contamination[5]. Incorrect doffing practices of HCWs was observed which can cause potential contamination of the HCW’s clothing or skin, with respect to the doffing sequence and doffing technique[6]. Nevertheless, few studies have reported evaluations of the disinfection effects of contaminated medical protective clothing or comparisons of anti-self-contamination effects of disinfectants and standard doffing procedures. Therefore, the aim of this study was to explore the decontamination efficacy and applicability of disinfectant use on medical protective clothing, as well as the importance of professional doffing.

The disinfection efficacy was evaluated using various microorganism standard strains as indicators. Bacteriophage phi X174 and host bacteria Escherichia coli ATCC 13706 were supplied by the Guangdong Microbial Culture Collection Center. Escherichia coli 8099 was supplied by the China General Microbiological Culture Collection Center. Wanjie disinfectant containing 44.6 g/L available chlorine was provided by Hangzhou Shikang Disinfection Products Co., LTD. Prior to the experiment, it was diluted with deionized water to 500 mg/L available chlorine, 1,000 mg/L available chlorine. Additional disinfectants used include 75% ethanol and Bilan alcohol wipes (Biruiya) containing 77%–82% ethanol was provided by Sinopharm and Hangzhou Biruiya Medical Technology Co., LTD. Neutralizers are DifcoTM D/E neutralizing broth and 0.5% sodium thiosulfate. The neutralizers could be used after the qualification of National Standard of the People’s Republic of China GB/T 38502–2020.

The bacteriophage suspension preparation and counting was based on the previous literature[7]. Escherichia coli ATCC 13706 and bacteriophage phi X174 were mixed with phosphate buffered saline (PBS). The mixed product was cultured on a nutrient agar plate at 37 °C for 6–7 hours and the excess liquid was aspirated, incubating at 37 °C for 16 hours. The bacteriophages were washed with PBS (adding chloroform) under 250 rpm shaking for 30 minutes and placed in a centrifuge at 5,000 rpm for 20 minutes. The bacteriophages’ supernatant was filtered through 0.22 μm filters. After that, the purified bacteriophage suspension was counted on a double-layer agar medium (lower medium: nutrient agar; upper medium: 10 g/L tryptone, 5.0 g/L NaCl, 1.0 g/L glucose, 6.0 g/L agar, 25 mmol/L CaCl2). Escherichia coli ATCC 13706 and bacteriophage were mixed in equal proportions and inoculated into the lower medium. Then, the upper medium was added and incubated at 37 °C for 3–4 hours. The bacteriophages’ titer (pfu/mL) was then calculated.

Carrier spray quantitative germicidal test was performed on a mannequin wearing Tychem C protective clothing (DuPont). First, a 10 mm × 10 mm piece of degreasing plain white cotton (sterilized) was used as the carrier. Escherichia coli 8099 or bacteriophage phi X174 suspension was diluted by tryptone soybean broth and dripped onto each carrier. The final recovery amount needed to reach 1 × 103 – 5 × 104 cfu bacteria per carrier or pfu bacteriophage per carrier. Then, carriers were each affixed to various parts of a mannequin wearing Tychem C protective clothing, specifically, on the front chest, back, arm, front leg, and back leg. Disinfectant containing 500 mg/L available chlorine, 1,000 mg/L available chlorine, and 75% ethanol were added to the automatic sprayer which was produced by Zhejiang TAILIN Bioengineering Company Limited. According to the parameters of the instrument, the spray pressure was 0.7 Mpa, the spray rate was 3 mL/s, and the spray liquid particle size was about 110 μm. The automatic sprayer sprayed the disinfectant on the mannequin at a distance of 0.5 meter and rotated 20 s/circle for 40 seconds. Then the disinfectants continued working for 3–15 minutes. The bacteria or bacteriophage carriers without the disinfectants were set up as positive controls. The carriers that had been used for the set times were placed into 10 mL of D/E neutralizing broth (75% ethanol) or 0.5% Na2S2O3 (chlorine-containing disinfectant). Finally, the bacteria killing or logarithmic inactivation values were counted.

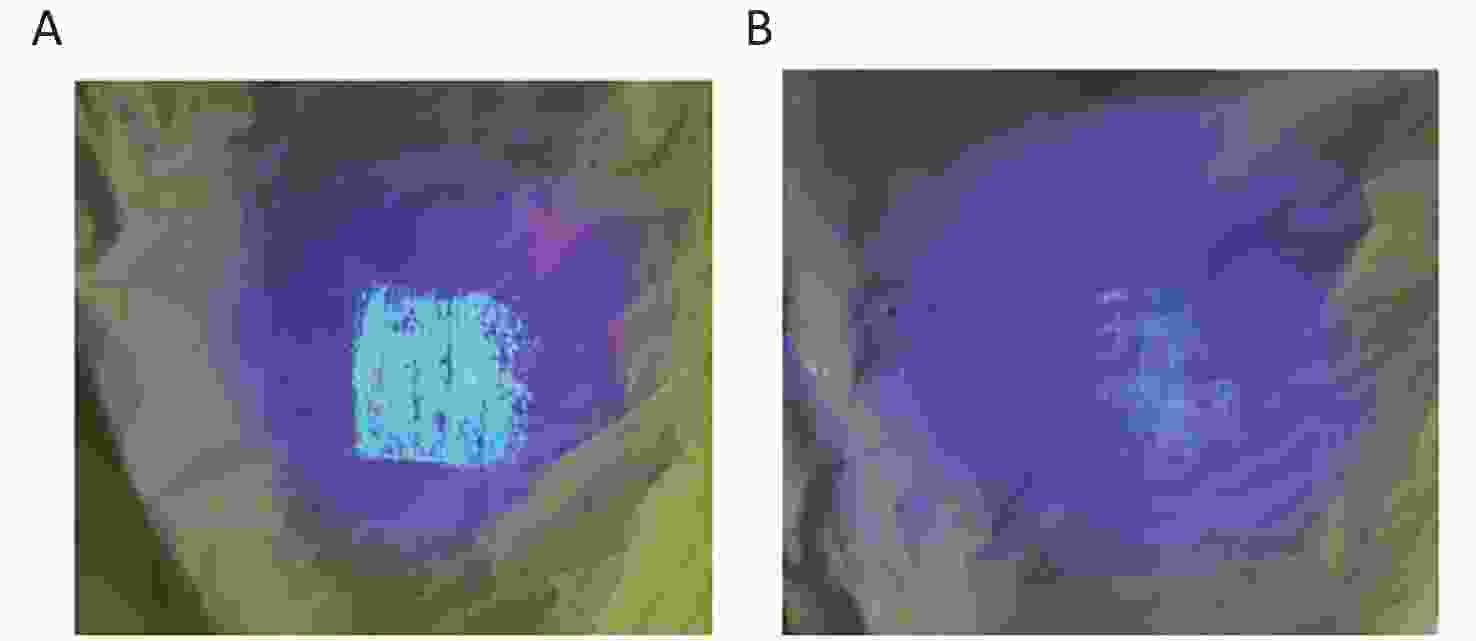

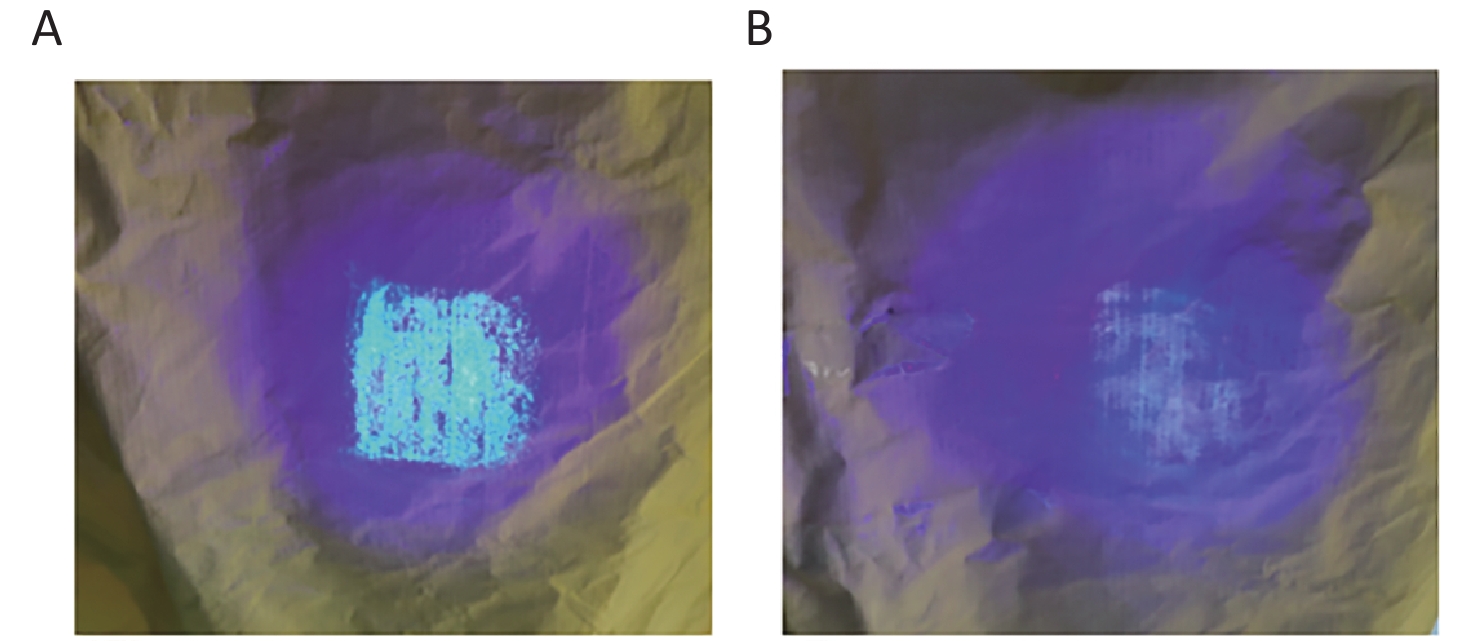

The eliminative effect of alcohol wipes was measured by the fluorescent indicator tracer (Enrichment Biotechnology). The fluorescent dye was applied on a 3 cm × 3 cm surface of Tychem C protective clothing. An ultraviolet flashlight was used to detect the fluorescence before and after alcohol wipes were used for 30 seconds.

To prepare the donning and doffing PPE test, an examiner professionally wore and doffed PPE according to a China health standard guideline of WS/T 311–2009 in a class 100 clean room. Meanwhile, the examiner daubed the fluorescent indicator tracer on the outer surface of the gloves, the connection between gloves and gown, the outside surface of the gown forearm, and the outside surface of the head cap within a 6 cm-diameter circle. An ultraviolet flashlight was applied to detect fluorescence on the clothes or skin before and after the professional removal of the PPE. Then, an HHPC6+ dust particle counter (MetOne) was used to monitor the dynamic change of the number of dust particles in the environment at a distance of 1 meter from the examiner taking off the PPE, and the height was 1.5 meters. The collection volume was 2.83 L/min, and the results were read every minute for a total of 4 minutes. The professional steps of removing PPE are hand hygiene - medical protective face shield - hand hygiene - medical protective clothing (DuPont), gloves - hand hygiene - medical non-woven cap - hand hygiene - N95 mask - hand hygiene[8]. All experiments were performed in triplicate.

Statistical analyses were performed using SPSS version 26.0 (SPSS Corp., Armonk, IL, 100 USA). Logarithmic killing value and logarithmic inactivation value were analyzed by Wilcoxon test. The number of dust particles were analyzed by t-test.

Bacteria killing test and bacteriophage inactivation test were used to identify the influence of disinfectants on disinfection effects of medical protective clothing. In order to completely kill Escherichia coli 8099 on the surface of all sites of medical protective clothing, a disinfectant with 1,000 mg/L available chlorine needs to be used for 3 minutes (the average logarithmic killing values were more than 2.76, 2.75) and 75% ethanol needs to be applied for 10 minutes (the average logarithmic killing value were more than 3.00, 2.82). Exposed to 500 mg/L available chlorine for 15 minutes, Escherichia coli 8099 could be reduce by more than 3.16 or 3.45 log. A prolonged disinfection time could enhance the logarithmic killing value of bacteria (P < 0.05). In addition, action sites of the disinfectant will also influence the killing effect on Escherichia coli, as the data shown in Table 1 demonstrates. The results suggested that spraying disinfectant with 1,000 mg/L available chlorine on the surface of medical protective clothing has a significantly greater bactericidal effect on Escherichia coli 8099 than 75% ethanol and 500 mg/L available chlorine. These two disinfectants need to be used for at least 10 minutes or 15 minutes to completely kill the bacteria on all zones of medical protective clothing.

Table 1. The killing effect of disinfectants and treatment time on Escherichia coli on medical protective clothing

Disinfectants Sites of medical protective clothing Average logarithmic killing value for treatment time (minute) Average colony logarithmic value of positive control group 3 5 10 15 75% ethanol Front chest 1.33 2.25 > 3.00 > 3.00 3.70 Back > 3.00 > 3.00 > 3.00 > 3.00 Arm > 3.00 > 3.00 > 3.00 > 3.00 Front leg 2.52 > 2.82 > 2.82 > 2.82 3.52 Back leg > 2.82 > 2.82 > 2.82 > 2.82 500 mg/L available chlorine Front chest 2.02 2.06 > 3.16 > 3.16 3.86 Back 1.33 1.58 3.00 > 3.16 Arm 1.07 1.23 1.72 > 3.16 Front leg 2.13 2.93 > 3.45 > 3.45 4.15 Back leg 1.13 2.61 2.75 > 3.45 1,000 mg/L available chlorine Front chest > 2.76 > 2.76 > 2.76 > 2.76 3.46 Back > 2.76 > 2.76 > 2.76 > 2.76 Arm > 2.76 > 2.76 > 2.76 > 2.76 Front leg > 2.75 > 2.75 > 2.75 > 2.75 3.45 Back leg > 2.75 > 2.75 > 2.75 > 2.75 In order to completely inactivate the bacteriophage phi X174 on the surface of all sites of medical protective clothing, a disinfectant with 500 mg/L available chlorine needs to be used for 5 minutes (the average logarithmic inactivate values were more than 3.51, 3.25). The disinfection time of 75% ethanol had significant effect on the logarithmic inactivation value of back, front and back leg front (P < 0.05). However, even a 15-minute 75% ethanol treatment revealed only poor efficacy against the bacteriophage phi X174; the average logarithmic inactivation value was 0.96 (0.92, 0.95, 1.01) and 0.65 (0.59, 0.71). In addition, some disinfectant action sites will also influence the inactivation effect of bacteriophage phi X174 (P < 0.05), as the data shown in Table 2 suggests. The results revealed that available chlorine has a greater inactivate effect on bacteriophage phi X174 than 75% ethanol. However, prolonging the disinfection time failed to achieve the complete inactivation effect due to the volatile nature of ethanol. Bacteriophage is used as an indicator virus for the demonstration of virus contamination and virus inactivation[7]. Its structure is similar to that of non-enveloped enteroviruses. Studies have also shown that 75% ethanol has a rather poor inactivation effect on human enterovirus 71 (logarithmic inactivation value < 1.00)[9]. Ethanol achieves antibacterial purposes by resolving the lipids in cell membranes. Thus, viruses or bacteriophages without envelopes might be more resistant to ethanol than microbes with envelopes. Chlorine-releasing agents are highly active oxidizing agents that can destroy the cellular activity of proteins and inhibit DNA synthesis[10]. This may lead to a more effective killing effect on bacteria and viruses. In addition, spraying sites will also influence the disinfection effect, which may be related to surface flatness, as well as the angle and uniformity of the spraying. In realistic cases, there were some problems with spraying disinfectants, such as insufficient action time, incomplete coverage of spraying sites and incorrect selection of disinfectants. Spraying actions may increase the risk of contamination. High doses of disinfectants might also cause safety hazards to HCWs and the environment.

Table 2. The Inactivation effect of disinfectants and treatment time on bacteriophage Phi X174 on medical protective clothing

Disinfectants Sites of medical protective clothing Average logarithmic inactivation value for treatment time (minute) Average titer logarithmic value of positive control group 3 5 10 15 75%

ethanolFront chest 0.50 0.73 0.80 0.95 4.03 Back 0.57 0.69 0.80 0.92 Arm 0.77 0.92 0.94 1.01 Front leg 0.29 0.38 0.51 0.59 3.83 Back leg 0.31 0.55 0.60 0.71 500 mg/L

available chlorineFront chest 2.24 > 3.51 > 3.51 > 3.51 4.21 Back 2.61 > 3.51 > 3.51 > 3.51 Arm 3.04 > 3.51 > 3.51 > 3.51 Front leg 1.25 > 3.25 > 3.25 > 3.25 3.95 Back leg 2.59 > 3.25 > 3.25 > 3.25 Furthermore, alcohol wipes elimination test was performed to evaluated removal effects of contamination. After using alcohol wipes on the surface of medical protective clothing for 30 seconds, the fluorescence intensity was reduced. But there can still be a small amount of fluorescent residue due to the pore structure of the surface, as shown in Supplementary Figure S1 (available in www.besjournal.com). This indicated that the wiping action of alcohol wipes has an evident effect on the elimination of contamination.

Figure S1. Alcohol wipes elimination test on the surface of medical protective clothing. (A) Before wiping with alcohol wipes; (B) After wiping with alcohol wipes.

Fluorescent indicator tracer test and dust particle counting test showed that the pollution impact in the doffing of PPE. After doffing the PPE by following the standard steps, there was no obvious fluorescent indicator residue on areas of the examiner’s body, such as the hands, the connection between gloves and gowns, forearm, or head, as shown in Figure 1A–H. During the removal of PPE, the number of 0.3 μm, 1 μm, 3 μm, 5 μm, and 10.0 μm size of dust particles in the surrounding environment had no statistically significant increased within 1–3 minutes (P > 0.05). The 0.3 μm, 0.5 μm, and 1.0 μm size of dust particles increased significantly at the fourth minute (P < 0.05), as shown in Figure 1. Therefore, the above findings showed that compared with the uncertain effects of different disinfection methods, correctly following the doffing procedures for PPE can effectively avoid self-contamination, but it will also increase dust particles in the environment. This number can reach the highest value at the fourth minute, which was presumed to be caused by the complete detachment of the medical protective clothing. Moreover, the China health standard guideline of WS/T 311–2009 also indicates that the medical protective mask can be removed after doffing PPE such as medical protective clothing and leaving the contaminated zone. These phenomenon prompts the assumption that there is a greater infection risk of pathogenic microorganisms through the respiratory tract in the later PPE doffing stages.

Figure 1. The pollution impact in the doffing of PPE. (A–D) Fluorescent indicator tracer test before doffing of PPE; (E–F) Fluorescent indicator tracer test after doffing of PPE; (A, E) Hand; (B, F) The connection between gloves and gowns; (C, G) Forearm; (D, H) Head; (I) The dust particle counting test during the removal of PPE. PPE, Personal protective equipment.

However, our study still has several limitations. First, non-enveloped viruses are more resistant to chemical disinfectants than enveloped viruses. Bacteriophage phi X174’s structure is similar to that of non-enveloped enteroviruses. This means that its experimental results were not representative of enveloped viruses. Second, it was necessary to expand the number of various personnel in the medical protective clothing removal experiment. Meanwhile, we lacked the analysis of the risk nodes that were prone to self-contamination and simultaneously tracking the changing trends of dust particles and airflow in the environment.

In conclusion, this study demonstrated that the decontamination efficacy of disinfection was profoundly influenced by many factors, such as the spraying sites, action times, the types of disinfection products and microorganisms. Correctly doffing PPE can effectively avoid self-contamination, but it also increased the number of dust particles in the environment.

doi: 10.3967/bes2023.142

Decontamination Efficacy of Disinfection and Doffing of Medical Protective Clothing: A Combined Mannequin and Personnel Study

-

XIE Zhong Yi, LU Long Xi and LU Ye contributed to the conception of the study; XIE Zhong Yi, LU Long Xi and FAN Ling Feng performed the experiment; XIE Zhong Yi, LU Long Xi, LI Ye and YANG Fan Fan contributed significantly to formal analysis and data curation; XIE Zhong Yi contributed to the writing original draft; LU Long Xi, LI Ye, YANG Fan Fan and LU Ye helped perform the review and editing with constructive discussions. All authors read and approved the final version of the manuscript.

The authors declare no competing interests.

&These authors contributed equally to this work.

注释:1) Author Contribution: 2) Conflict of Interest: -

Figure 1. The pollution impact in the doffing of PPE. (A–D) Fluorescent indicator tracer test before doffing of PPE; (E–F) Fluorescent indicator tracer test after doffing of PPE; (A, E) Hand; (B, F) The connection between gloves and gowns; (C, G) Forearm; (D, H) Head; (I) The dust particle counting test during the removal of PPE. PPE, Personal protective equipment.

Table 1. The killing effect of disinfectants and treatment time on Escherichia coli on medical protective clothing

Disinfectants Sites of medical protective clothing Average logarithmic killing value for treatment time (minute) Average colony logarithmic value of positive control group 3 5 10 15 75% ethanol Front chest 1.33 2.25 > 3.00 > 3.00 3.70 Back > 3.00 > 3.00 > 3.00 > 3.00 Arm > 3.00 > 3.00 > 3.00 > 3.00 Front leg 2.52 > 2.82 > 2.82 > 2.82 3.52 Back leg > 2.82 > 2.82 > 2.82 > 2.82 500 mg/L available chlorine Front chest 2.02 2.06 > 3.16 > 3.16 3.86 Back 1.33 1.58 3.00 > 3.16 Arm 1.07 1.23 1.72 > 3.16 Front leg 2.13 2.93 > 3.45 > 3.45 4.15 Back leg 1.13 2.61 2.75 > 3.45 1,000 mg/L available chlorine Front chest > 2.76 > 2.76 > 2.76 > 2.76 3.46 Back > 2.76 > 2.76 > 2.76 > 2.76 Arm > 2.76 > 2.76 > 2.76 > 2.76 Front leg > 2.75 > 2.75 > 2.75 > 2.75 3.45 Back leg > 2.75 > 2.75 > 2.75 > 2.75 Table 2. The Inactivation effect of disinfectants and treatment time on bacteriophage Phi X174 on medical protective clothing

Disinfectants Sites of medical protective clothing Average logarithmic inactivation value for treatment time (minute) Average titer logarithmic value of positive control group 3 5 10 15 75%

ethanolFront chest 0.50 0.73 0.80 0.95 4.03 Back 0.57 0.69 0.80 0.92 Arm 0.77 0.92 0.94 1.01 Front leg 0.29 0.38 0.51 0.59 3.83 Back leg 0.31 0.55 0.60 0.71 500 mg/L

available chlorineFront chest 2.24 > 3.51 > 3.51 > 3.51 4.21 Back 2.61 > 3.51 > 3.51 > 3.51 Arm 3.04 > 3.51 > 3.51 > 3.51 Front leg 1.25 > 3.25 > 3.25 > 3.25 3.95 Back leg 2.59 > 3.25 > 3.25 > 3.25 -

[1] Cui C, Yao Q, Zhang D, et al. Approaching otolaryngology patients during the COVID-19 pandemic. Otolaryngol Head Neck Surg, 2020; 163, 121−31. doi: 10.1177/0194599820926144 [2] Rowan NJ, Laffey JG. Unlocking the surge in demand for personal and protective equipment (PPE) and improvised face coverings arising from coronavirus disease (COVID-19) pandemic - Implications for efficacy, re-use and sustainable waste management. Sci Total Environ, 2021; 752, 142259. doi: 10.1016/j.scitotenv.2020.142259 [3] Karim N, Afroj S, Lloyd K, et al. Sustainable personal protective clothing for healthcare applications: a review. ACS Nano, 2020; 14, 12313−40. doi: 10.1021/acsnano.0c05537 [4] Polanczyk A, Piechota-Polanczyk A, Dmochowska A, et al. Analysis of the effectiveness of decontamination fluids on the level of biological contamination of firefighter suits. Int J Environ Res Public Health, 2020; 17, 2815. doi: 10.3390/ijerph17082815 [5] Verbeek JH, Rajamaki B, Ijaz S, et al. Personal protective equipment for preventing highly infectious diseases due to exposure to contaminated body fluids in healthcare staff. Cochrane Database Syst Rev, 2020; 4, CD011621. [6] Phan LT, Maita D, Mortiz DC, et al. Personal protective equipment doffing practices of healthcare workers. J Occup Environ Hyg, 2019; 16, 575−81. doi: 10.1080/15459624.2019.1628350 [7] Chen ZB, Huang HY, Zhang CW. Comparative study of the resistance of bacteriophageT4, ФX174D, MS2 and f2 to gamma radiation. Natl Med J China, 2008; 88, 198−201. (In Chinese [8] Qiu YX, Ye BL, Dong QF, et al. Effective training approach of personal protection of COVID-19. Chin J Infect Control, 2020; 19, 513−7. (In Chinese [9] Chang SC, Li WC, Huang KY, et al. Efficacy of alcohols and alcohol-based hand disinfectants against human enterovirus 71. J Hosp Infect, 2013; 83, 288−93. doi: 10.1016/j.jhin.2012.12.010 [10] McDonnell G, Russell AD. Antiseptics and disinfectants: activity, action, and resistance. Clin Microbiol Rev, 1999; 12, 147−79. doi: 10.1128/CMR.12.1.147 -

23170+Supplementary Materials.pdf

23170+Supplementary Materials.pdf

-

下载:

下载:

Quick Links

Quick Links